Description

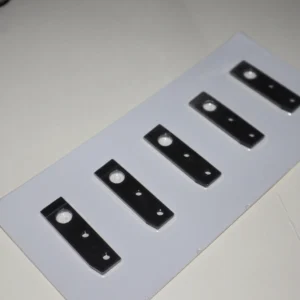

Description of BE208333 Step Motor for Gamma and Gammax Picanol Looms

The BE208333 Step Motor is a critical component used in Picanol Gamma and Gammax series looms. This step motor is responsible for precise control of mechanical movements within the loom, contributing to accurate and consistent weaving processes.

Key Features:

- Model: BE208333

- Type: Step Motor

- Compatibility: Designed for use in Picanol Gamma and Gammax weaving machines.

- Function: Controls the rotational motion of various loom components, ensuring accurate positioning and timing.

- Durability: Built to withstand the rigorous demands of high-speed weaving, providing long-term reliability and performance.

Application:

The step motor plays a crucial role in synchronizing the movements of the loom’s components, enabling the production of high-quality fabric with precise patterns and minimal defects. Its reliability is essential for maintaining the efficiency and productivity of the weaving process.

How does the step motor work in weaving looms?

Working of step motor in Weaving Looms:

A step motor, like the BE208333 used in Picanol Gamma and Gammax looms, plays a crucial role in the precise control of various machine components. Here’s how it functions in the context of a weaving loom:

1. Precision Control:

- Incremental Movement: Unlike regular motors, step motors move in discrete steps, allowing for precise control over the position of the loom’s components. Each step corresponds to a specific degree of rotation, ensuring that the motor can move to an exact position and hold it without feedback mechanisms.

2. Synchronization:

- Coordinated Actions: In a weaving loom, multiple processes must be synchronized, such as the movement of the warp and weft threads, the operation of the shedding mechanism, and the control of the reed. The step motor ensures that these components move in perfect harmony, contributing to the production of uniform fabric.

3. Variable Speed:

- Adaptability: The step motor can adjust its speed based on the requirements of the weaving process. For instance, it can operate at a slower pace for delicate fabrics requiring fine adjustments or at a higher speed for standard weaving tasks.

4. Positioning:

- Accurate Weft Insertion: In the context of weft insertion, the step motor controls the position of the insertion device, ensuring that the weft thread is placed correctly in each cycle. This accuracy is vital for maintaining the pattern and quality of the fabric.

5. Feedback and Adjustment:

- Error Correction: Step motors often work in conjunction with sensors that detect the position of loom components. If a misalignment or error is detected, the motor can make real-time adjustments, correcting the position and ensuring continuous, error-free operation.

Role in Overall Loom Operation

- Quality Control: The step motor’s precision directly impacts the quality of the fabric being produced. Consistent operation reduces the risk of defects, such as misaligned threads or uneven patterns.

- Efficiency: By automating and precisely controlling the movements within the loom, step motors contribute to higher operational efficiency, allowing for faster production without sacrificing quality.

Reviews

There are no reviews yet.